|

|

|

|

|

|

|

|

|

|

|

|

|

The Final Solution |

|

| |

SD spigot connector for arc welding tempered with ceramic ferule or protection gas.

Connector bolts are metal elements that, when welded to the base section or plate, act as concrete anchoring on steel with regard to tensile strength making up composite beams.

These devices used to solidify steel and concrete into a composite piece, must present adequate material quality for the welding technique used and their mechanical properties must verify:

• The tensile strength/elastic limit ratio.

• The deformation with breakage.

The geometry of NARON SD bolts, together with their dimensions, are compliant with Standard EN ISO 13918: 2008.

|

|

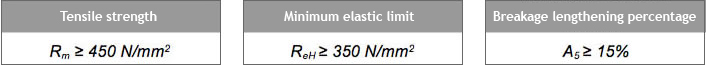

Mechanical properties:

NAKRON SD connector bolts are manufactured in accordance with standard ISO EN13918:2008 and their mechanical properties comply with the regulations demanded in this standard, as shown in the following table:

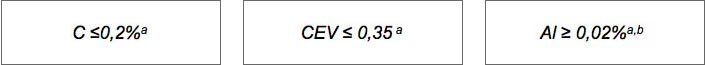

Material and Chemical Composition:

NAKRON SD spigot connectors are manufactured with Group 1steel according to the steel grouping system of standard ISO/TR 15608, whose values refer to the analysis of material casting.

Bolts will be welded to the base plate using an automatic procedure by means of a special gun enabling their placement. The variations in the welding process refer to the protection of the weld bath, either using a ceramic ferule or by means of a protective gas.

Ceramic Ferule:

This forms a combustion chamber around the area to be welded, concentrating the arc in a reduced area and limiting heat losses and the cooling speed of the weld bath and displacing the molten metal, forming a collar around the bolt.

Welding may be performed in any position and the ferule is used only once, as it is eliminated when the molten metal solidifies.

The minimum thickness of the base plate will be ¼ of the bolt diameter and never under 1mm.

Protective Gas:

The atmosphere in the arc area is replaced with a protective gas (82% argon, 18% carbon dioxide), reducing the formation of blow holes. This has an influence on the arc, the welding of the bolt and the base plate, it modifies the surface tension of the weld bath and, therefore, the shape of the collar and the penetration. It may be used with a ceramic ferule.

The minimum thickness of the base plate will be ⅛ of the bolt diameter and never under 1mm.

A welding process without a protective gas may be used but only for bolts with ∅≤ 10mm and using a short-cycle welding system.

|

| |

|

|

| |

NAKRON STUD S.L.

Calle La Iglesia 33, bajo E

33180 - Noreña, Principado de Asturias, Spain

|

|

|

|

|